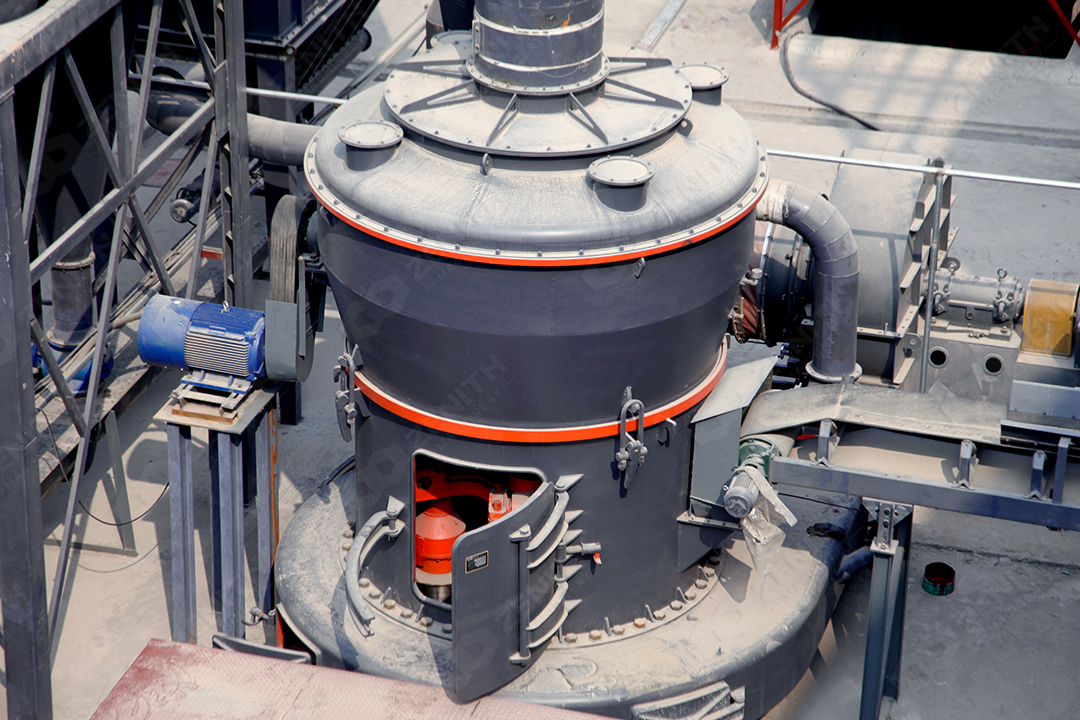

Rare earth grinding equipment mtw european version grinding mill

2025-12-27 00:55:30

In the demanding world of mineral processing, particularly for critical materials like rare earth elements, the efficiency and precision of grinding equipment are paramount. These elements, essential for modern technologies from smartphones to electric vehicles and defense systems, require specialized handling to liberate their value without compromising their unique properties. For over three decades, Shanghai Zenith Machinery Co., Ltd. has been at the forefront of industrial powder grinding technology, developing solutions that meet the exacting standards of global industries. Among our flagship products, the MTW European Version Grinding Mill stands out as a premier choice for processing a wide range of materials, including rare earth ores, into fine and ultra-fine powders.

The MTW European Trapezium Mill represents a significant evolution in grinding technology. Engineered for stability and high capacity, it is designed to produce fine powders ranging from 80 to 400 mesh, with the largest models achieving outputs of up to 50 tons per hour. This makes it an ideal workhorse for operations where consistent, high-volume production is required. Its application extends beyond rare earths into agriculture, chemicals, paints, steel plants, and water treatment, showcasing its versatility.

_1766768130741.jpg)

One of the most compelling advantages of the MTW mill is its remarkable energy efficiency. Under ideal working conditions, it consumes more than 60% less energy compared to a traditional ball mill of the same grade. This is not just a cost-saving measure; it aligns with global sustainability goals, reducing the carbon footprint of mineral processing operations. Furthermore, the mill's integrated design—from bulk material handling to finished powder collection—minimizes the required plant footprint and foundational investment, offering a compact and cost-effective production system.

Precision in product fineness is non-negotiable in rare earth processing. The MTW mill addresses this with an innovative modular impeller adjustment device. Operators can easily alter the fineness of the output product simply by changing the impellers, allowing for flexible production schedules to meet specific customer requirements for different applications. This adjustability, combined with a high-efficiency impeller fan that boosts air induction efficiency from 62% to 85%, ensures optimal classification and consistent powder quality.

_1766768130745.jpg)

The working principle of the MTW mill is a model of efficient, closed-loop processing. After initial crushing, materials are fed into the main grinding chamber via a variable frequency belt feeder. The ground material is then conveyed by fan airflow to a powder selector for precise classification. Qualified fine powder is separated as finished product in a cyclone collector, while coarse particles are returned for re-grinding. The entire system operates under controlled positive and negative pressure and is equipped with a pulse dust collector, ensuring that operations meet stringent international environmental protection standards.

Zenith's commitment to quality is underscored by our equipment's certifications, including ISO, European Union CE, and Customs Union CU-TR. Our global network, spanning over 180 countries with offices in more than 30, ensures that support and expertise are always within reach. For processors of rare earths and other high-value minerals, the MTW European Version Grinding Mill offers a reliable, efficient, and adaptable solution, engineered to deliver the fine powder consistency demanded by advanced technological applications.

Frequently Asked Questions (FAQs)

- What is the typical output fineness range of the MTW European Grinding Mill for rare earth processing?

The MTW mill is capable of producing fine powder in the range of 30 to 325 mesh (approximately 45 microns to 500 microns). For rare earth applications requiring specific liberation sizes, the modular impeller system allows for precise adjustment within this spectrum. - How does the energy consumption of the MTW mill compare to a traditional ball mill?

The MTW European Trapezium Mill demonstrates superior energy efficiency, consuming over 60% less energy than a ball mill of equivalent grade and output under comparable working conditions. - Can the MTW mill handle materials other than rare earth ores?

Absolutely. While excellent for rare earths, the MTW mill is a versatile grinding solution widely used for processing materials in the chemical, agricultural, paint, construction (wall putty), and metallurgical industries. - What kind of dust control system does the mill incorporate?

The system operates under a sealed, negative-pressure design and is equipped with a high-efficiency pulse jet bag dust collector. This effectively contains dust, ensuring a clean working environment and full compliance with environmental regulations. - Is the output fineness easily adjustable, and how is it done?

Yes, fineness adjustment is straightforward. The mill utilizes a modular impeller adjustment device. By changing or adjusting the impellers in the classifier, operators can control the product fineness without stopping the grinding process. - What is the maximum feed size for the MTW series mills?

The maximum input size for the MTW European Grinding Mill is 35mm. Proper pre-crushing to this size ensures optimal grinding efficiency and equipment longevity. - Does Zenith provide support for installation and maintenance?

Yes. With overseas offices in over 30 countries and a global service network, Zenith provides comprehensive technical support, installation guidance, operator training, and after-sales service for all our grinding equipment.