Working principle and applicable material range of european-style grinding mill

2025-12-25 00:53:59

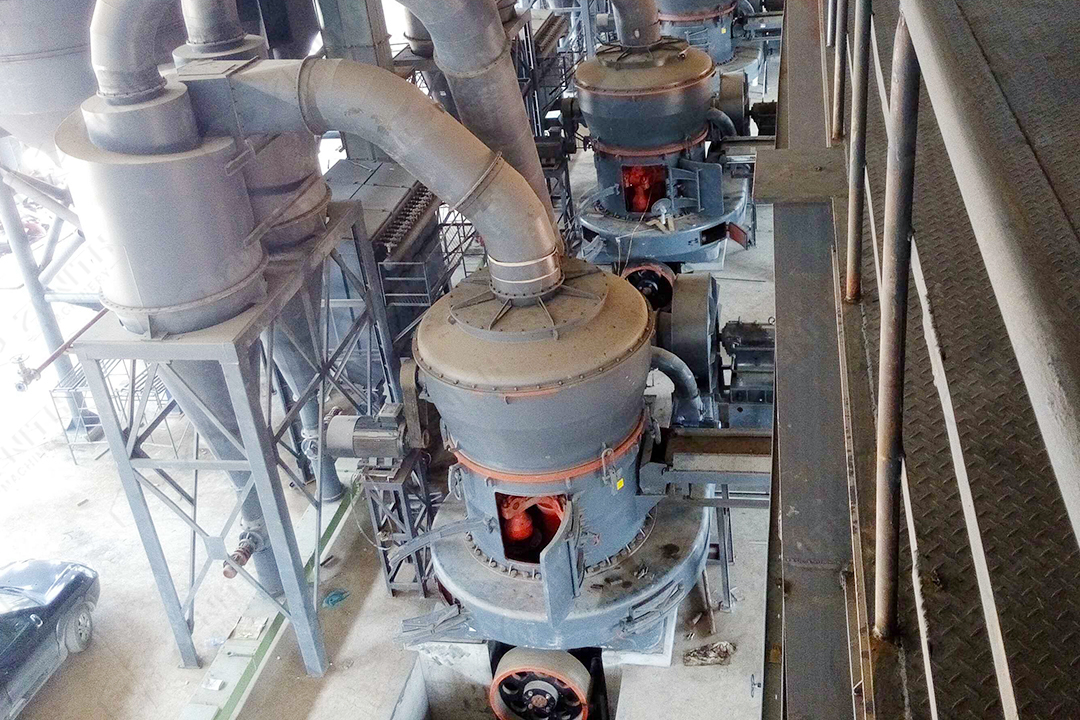

In the modern industrial landscape, the demand for efficient, precise, and versatile powder processing is paramount. At the forefront of this technological evolution are European-style grinding mills, a category of equipment renowned for their advanced engineering, energy efficiency, and broad material adaptability. Drawing from decades of research and development, our company's portfolio, including the flagship MTW and MTM European Trapezium Mills, embodies the core principles of this technology, serving a global clientele across diverse sectors from construction and chemicals to agriculture and advanced materials.

The fundamental working principle of these mills revolves around a closed-circuit grinding and classification system. The process begins with pre-crushed raw material, typically under 35mm in size, being fed into the grinding chamber via a controlled feeder. Within the chamber, the material is subjected to compressive and shear forces between rotating grinding rollers and a stationary grinding ring or disc. This mechanical action reduces the material to finer particles.

_1766595239021.jpg)

Following the initial grinding, an integral high-efficiency impeller fan induces an airflow that carries the pulverized material upward to a dynamic powder classifier or separator. This is the heart of fineness control. The classifier, often equipped with a variable-frequency drive (VFD), acts as a precision gatekeeper. It uses centrifugal force and airflow to separate particles based on size. Coarse particles, rejected by the classifier's rotating blades, fall back into the grinding chamber for further comminution. Meanwhile, fine powder that meets the target specification (ranging from 80 to 400 mesh for trapezium mills, and up to 3250 mesh for ultrafine models) is carried by the airflow through pipelines into a cyclone powder collector and a pulse-jet bag filter for product separation and collection. The entire system operates under negative pressure, ensuring no dust emission and a clean working environment.

The applicability of European-style mills is vast, largely due to their adjustable operational parameters and robust design. The MTW and MTM European Trapezium Mills are workhorses for medium-fine powder production. They excel in processing non-metallic minerals like limestone, calcite, dolomite, barite, talc, and gypsum. These materials are foundational for industries such as paint and coatings, plastics, rubber, agriculture (fertilizers, pesticides), construction (wall putty, dry mortar), and chemical manufacturing. Their stable performance and high capacity (up to 50 TPH) make them ideal for large-scale production lines.

For applications demanding even finer powders or specialized processing, vertical roller mills (VRMs) like the LM and LUM series offer distinct advantages. The LM Vertical Grinding Mill, with its capacity for 24-hour continuous operation and high degree of automation, is perfectly suited for massive projects in cement clinker grinding, slag (GGBS) production, and coal preparation. Its grinding principle involves a bed of material crushed between rollers and a rotating table, promoting inter-particle comminution for high efficiency. The LUM Ultrafine Vertical Mill, integrating advanced grinding roller and powder separating technology, pushes the boundaries into the ultrafine realm (325-2500 mesh). It is the equipment of choice for high-value products like high-grade calcium carbonate for plastics and paper, titanium dioxide, and various functional fillers used in masterbatch, PVC, and artificial stone.

Key technological features that define the European-style mill's superiority include significant energy savings—consuming over 60% less power than traditional ball mills of the same grade—and a compact, integrated design that reduces footprint and civil engineering costs. The modular impeller adjustment system allows for quick changes in product fineness without stopping production, providing exceptional flexibility to meet varying market demands.

_1766595239025.jpg)

Beyond the trapezium and vertical mills, our engineering solutions extend across the entire particle size spectrum. For coarse powder (0-3mm), the HM Series Hammer Mill employs impact crushing, ideal for animal feed and dry mortar. For the most demanding ultrafine applications (325-3250 mesh), the XZM Ultrafine Grinding Mill offers single-step classification with D97 below 5 microns. Traditional yet reliable Ball Mills and Mining Ball Mills cater to wet or dry grinding of ores and raw materials in mining and cement industries. Each model is backed by international certifications like ISO, CE, and CU-TR, ensuring quality and reliability for our customers in over 180 countries.

In conclusion, the European-style grinding mill is not a single machine but a philosophy of efficient, clean, and adaptable size reduction. By mastering the synergy between mechanical grinding, aerodynamic classification, and intelligent control, these mills unlock the potential of a staggering array of materials, transforming raw resources into the fine powders that drive modern industry forward.

Frequently Asked Questions (FAQs)

- What is the main difference between MTW European Trapezium Mill and a traditional Raymond Mill?

The MTW mill features a more advanced curved blade design for its impeller fan (85% efficiency vs. 62%), a modular impeller adjustment system for easier fineness change, and an overall more streamlined internal airflow path. This results in higher output, lower energy consumption, and more stable operation compared to traditional designs. - Can your European-style mills handle hard and abrasive materials?

Yes, but with considerations. Mills like the MTM and LM series are equipped with wear-resistant grinding rollers and rings. For extremely hard or highly abrasive materials, we recommend specific high-chromium or ceramic wear parts and may adjust the grinding pressure and speed to optimize service life and efficiency. - How is the final product fineness precisely controlled?

Fineness is primarily controlled by the speed of the classifier's rotating blades, adjustable via a VFD on the control panel. Increasing the speed allows only finer particles to pass, resulting in a finer product. The grinding roller pressure and feed rate are secondary parameters that can be fine-tuned for optimal performance. - What are the dust collection and environmental protections in place?

The system operates under negative pressure. All milling and conveying stages are sealed. A high-efficiency pulse-jet bag dust collector is integrated, typically ensuring dust emissions are below 20 mg/Nm³, which meets strict international environmental standards. - What is the typical lead time for a complete grinding mill system?

Lead time depends on the model and configuration. Standard models typically have a lead time of 30-45 days after order confirmation. For large, customized systems involving multiple components, the timeline can extend to 60-90 days. We provide detailed project schedules upon quotation. - Do you provide installation and commissioning services overseas?

Yes. We have a team of experienced engineers who can provide remote guidance and, if required by contract, travel to the customer's site for installation supervision, commissioning, and operator training. We also provide comprehensive operation and maintenance manuals. - How does the energy consumption of an LM Vertical Mill compare to a ball mill for the same task?

The LM Vertical Mill is significantly more energy-efficient. For grinding cement raw material or slag to a similar fineness, the LM mill can reduce specific energy consumption by 30% to 50% compared to a traditional ball mill system, due to its focused bed-grinding principle and efficient separator.