Recommended rotary kiln light-burned dolomite grinding equipment

2025-12-24 00:57:28

In the production of light-burned dolomite, the rotary kiln process is just the beginning. The subsequent grinding stage is critical for determining the final product's reactivity, particle size distribution, and suitability for applications in steelmaking, agriculture, glass manufacturing, and environmental remediation. Selecting the optimal grinding equipment is not merely a procurement decision; it's a strategic investment in product quality, operational efficiency, and long-term profitability. At Zenith, with our global engineering expertise and decades of focus on industrial comminution, we understand these stakes intimately. This article distills our knowledge to recommend the most effective grinding solutions for your light-burned dolomite output.

Light-burned dolomite, calcined at temperatures between 700-1000°C, possesses a specific friability and crystal structure that demands a tailored grinding approach. The goal is to achieve a precise fineness—often ranging from 80 mesh for soil conditioning to 325 mesh or finer for specialized industrial fillers—without compromising the material's chemical properties or introducing excessive iron contamination. The equipment must handle a moderately abrasive feed with consistency, energy thrift, and minimal operational footprint.

Core Grinding Solutions for Light-Burned Dolomite

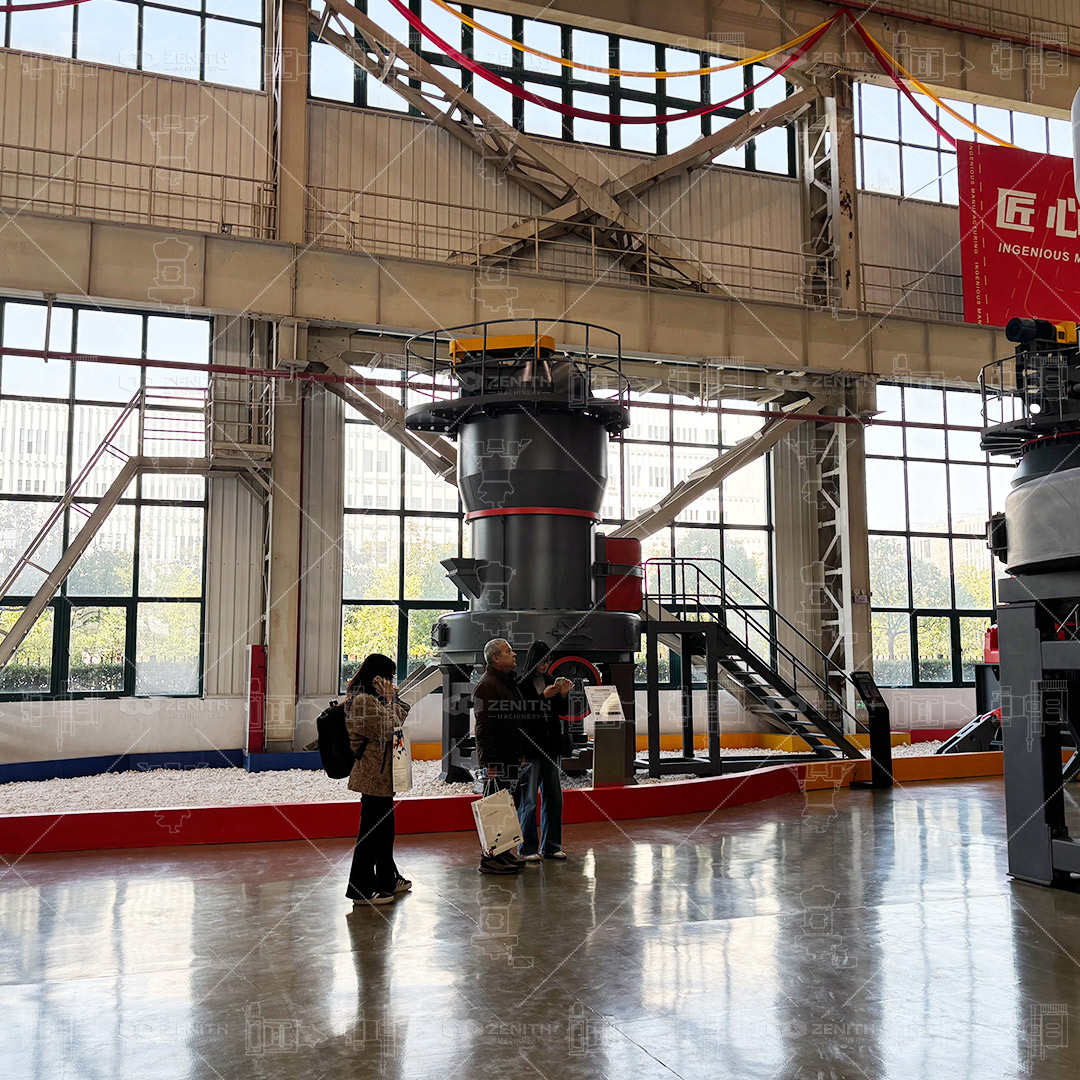

Based on extensive field applications and material testing, Zenith's European-origin trapezium mill series stand out as the premier workhorses for light-burned dolomite grinding in the 80-400 mesh range. The MTW European Trapezium Mill and MTM European Trapezium Mill are engineered for this exact purpose. Their design philosophy centers on creating a complete, self-contained powder production system. From receiving kiln-output material (typically 0-35mm), these mills grind, classify, and collect finished powder in one integrated loop. This translates to less plant space requirement and a significantly lower foundational investment compared to traditional, multi-component ball mill circuits.

The most compelling advantage is their dramatic energy efficiency. Under ideal working conditions, both MTW and MTM series consume over 60% less energy than a ball mill of equivalent output grade. This is achieved through an advanced grinding curve and a high-efficiency impeller fan that boosts air induction efficiency from 62% to 85%. For operators processing light-burned dolomite around the clock, this efficiency directly and substantially reduces the largest variable cost in grinding: power.

_1766509048361.jpg)

Advanced & Specialized Finishing Options

For producers targeting ultra-fine or coated fillers where superior whiteness and purity are paramount, Zenith's vertical roller mills offer a technologically advanced solution. The LM Vertical Grinding Mill excels in high-capacity, automated operations. Its sealed, negative-pressure operation ensures no dust spillage and protects the product's purity by minimizing iron wear contamination—a key concern for high-value dolomite applications. With capacity up to 340 T/H and the ability for 24-hour constant running, it is ideal for large-scale mineral powder plants.

When the product specification calls for micronized powders (325-2500 mesh), the LUM Ultrafine Vertical Grinding Mill is the equipment of choice. Integrating German powder separating technology, it delivers exceptional control over particle size distribution and chemical consistency. Its energy-saving design reduces consumption by 30-50% compared to ordinary ultrafine mills, while the hydraulic adjustment system allows for quick maintenance of grinding rollers—minimizing downtime. For the finest ranges up to 3250 mesh, the XZM Ultrafine Grinding Mill, with its variable frequency drive (VFD) classifier, allows arbitrary fineness adjustment from the control panel, ensuring pinpoint accuracy for niche chemical and plastic masterbatch industries.

_1766509048363.jpg)

Complementary Systems for Complete Processing Lines

A holistic grinding circuit often requires pre-processing. For light-burned dolomite that may contain occasional oversized lumps from the kiln, Zenith's HM Series Hammer Mill provides an efficient coarse grinding (0-3mm) stage with high grinding ratio and stable performance, ensuring a consistent feed for the fine grinding mills. Conversely, for operations that also require sand production or very coarse powder, the LM-Y Vertical Pre-grinding Roller Mill offers remarkable versatility, integrating sand-making and grinding functions.

While Zenith provides advanced alternatives, we also recognize scenarios where traditional Ball Mills and Mining Ball Mills are specified. Our designs in this category feature high adaptability, the option for wet or dry grinding, and robust construction with wear-resistant liners. However, for light-burned dolomite specifically, the superior energy economy and finer control offered by our trapezium and vertical mills typically present a more advantageous total cost of ownership.

Why Zenith is the Strategic Partner for Your Grinding Needs

Our recommendation is backed by more than just machinery specifications. Zenith's global footprint—with a marketing network covering over 180 countries and overseas offices in more than 30—ensures localized technical support and spare parts availability. Our equipment carries ISO, CE, and CU-TR certifications, guaranteeing international standards of quality and safety. We don't just sell a mill; we provide a production system solution, from initial material testing and plant layout assistance to commissioning and operational training.

The journey from rotary kiln output to market-ready light-burned dolomite powder is defined by the grinding step. By choosing equipment engineered for your material's specific characteristics and your production goals, you secure a foundation for quality, efficiency, and competitiveness. Zenith's portfolio, from the stalwart MTW/MTM mills to the cutting-edge LUM and XZM systems, is designed to be that foundation.

_1766509048367.jpg)

Frequently Asked Questions (FAQ)

- What is the primary advantage of using an MTW Mill over a traditional Ball Mill for light-burned dolomite?

The primary advantages are significantly higher energy efficiency (over 60% lower consumption), a more compact integrated system reducing plant footprint, and superior air classification leading to more consistent product fineness with less over-grinding. - Can your grinding equipment handle the slight abrasiveness of dolomite without excessive wear?

Yes. Our mills are constructed with high-quality, abrasion-resistant materials for vulnerable parts. For instance, grinding rollers and rings use special alloy steels, and designs like the LUM mill allow for easy replacement of wear parts to maintain performance and longevity. - We need to produce several different fineness grades from the same kiln output. Is this possible with one machine?

Absolutely. Mills like the MTW, MTM, and XZM feature adjustable classification systems. The XZM's VFD classifier, for example, allows you to change the product fineness arbitrarily between 325 and 2500 mesh directly from the control panel without stopping production. - How does your equipment ensure the final powder product remains pure and free from iron contamination?

Our vertical mills (LM, LUM) operate under negative pressure in a fully sealed environment. Furthermore, they are designed to minimize metal-to-metal contact in the grinding zone, and any incidental iron debris is automatically separated and discharged through a dedicated trap device, protecting product whiteness. - What kind of after-sales support and service can we expect globally?

Zenith provides comprehensive global support, including remote technical assistance, on-site engineer dispatch for installation and major maintenance, readily available spare parts through our overseas offices, and operational training for your personnel. - Is your equipment compliant with strict international environmental regulations?

Yes. All our grinding systems are equipped with high-efficiency pulse dust collectors (bag filters) and operate under negative or balanced pressure, ensuring dust-free operation, minimal noise, and full compliance with international environmental protection standards like those in the EU and North America. - What is the typical lead time for a complete grinding system from inquiry to commissioning?

Lead times vary based on the model and system complexity. However, our standardized design and manufacturing processes allow for efficient production. A detailed timeline can be provided upon receipt of your specific capacity and configuration requirements. - Do you offer testing services for our specific light-burned dolomite sample before we decide on equipment?

Yes, we strongly recommend and offer material testing services at our facilities or through collaboration with local partners. Testing determines the optimal mill type, configuration, and expected performance metrics (throughput, power draw, wear rates) for your exact material.