For grinding barite to 140 mesh, choose the lm vertical roller mill.

2026-02-10 00:54:36

In the industrial minerals processing sector, achieving consistent, high-volume production of fine powders like barite is a critical challenge. Barite, a mineral primarily composed of barium sulfate, is essential in applications ranging from oil and gas drilling fluids to paints, plastics, and pharmaceuticals. When the target is a precise 140-mesh (approximately 106 microns) product, the selection of grinding equipment becomes paramount. While several mills are capable of fine grinding, the LM Vertical Roller Mill (VRM) from Zenith emerges as the superior, holistic solution for this specific task, balancing efficiency, reliability, and operational economy.

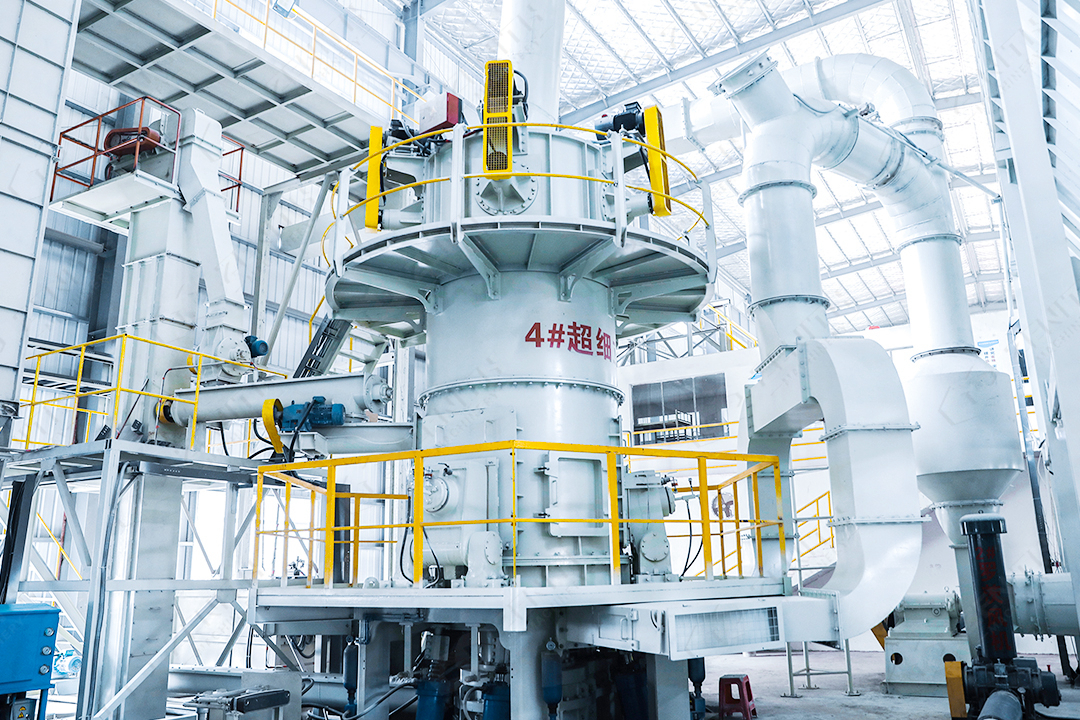

Zenith, a hi-tech engineering group specializing in industrial powder grinding, offers a comprehensive portfolio. For coarse powders (1-3mm), the Hammer Mill excels. For fine powders in the 20-400 mesh range, options include the Raymond Mill, MTM, and MTW European Trapezium Mills. For ultrafine (400-1250 mesh) and micro powders (1250-3250 mesh), the LUM Ultrafine Vertical Mill and XZM Ultrafine Grinding Mill are unparalleled. However, for the robust, continuous, and high-capacity production of barite at 140 mesh, the LM Vertical Grinding Mill stands out as the optimal workhorse.

The core advantage of the LM Vertical Roller Mill lies in its design philosophy: 24-hour constant running capability. This is not merely a feature but a fundamental operational principle. The mill's fully automated control system allows for seamless remote or local operation, ensuring stable product quality with minimal human intervention. For a barite processing plant aiming for maximum uptime and consistent output fineness, this automation translates directly into predictable profitability and reduced labor costs.

When processing minerals like barite, product purity is often as crucial as fineness. The LM mill excels here by effectively controlling product size, chemical composition, and critically, iron contamination. Its grinding mechanism—where material is crushed between rollers and a rotating disc—minimizes direct metal-to-metal contact compared to traditional ball mills. This results in a whiter, higher-purity barite powder, a key selling point for premium applications in paints and plastics.

_1770656076912.jpg)

Let's address the critical metrics of investment and operational cost. The LM VRM adopts a compact, integrated design, occupying approximately 50% less space than a ball mill system of equivalent capacity. This drastically reduces requirements for building and foundation, lowering initial capital expenditure. More significantly, its energy efficiency is remarkable. Under ideal conditions, the energy consumption of an LM mill is more than 60% lower than a ball mill of the same grade. For an energy-intensive process like grinding, this saving constitutes a major portion of the lifetime operating cost, offering a rapid return on investment.

Environmental compliance is non-negotiable in modern industry. The LM mill operates under a fully sealed, negative-pressure system. This design ensures no dust spillage during operation, coupled with low vibration and noise levels. The integrated pulse dust collector meets stringent international environmental standards, allowing plants to operate sustainably in sensitive regions. This eco-friendly profile aligns perfectly with global trends and regulatory demands.

_1770656076913.jpg)

The working principle of the LM mill is elegantly efficient for barite. The main motor drives the grinding disc via a reducer. Barite feedstock (0-70mm) falls to the disc's center and moves outward by centrifugal force, forming a uniform material bed. Hydraulically loaded rollers exert pressure, crushing the barite. The ground material is carried by a hot air stream to an integrated separator. At the target 140 mesh, fine powder passes through and is collected, while oversize particles are returned for re-grinding. This closed-loop system ensures precise particle size control and high grinding efficiency.

While the MTW or MTM Trapezium Mills are excellent for general fine powder production, and the LUM is ideal for ultrafine barite applications, the LM Vertical Roller Mill is uniquely positioned for the 80-400 mesh range where high tonnage, continuous operation, and low total cost of ownership are the primary drivers. Its capacity range of 3-340 T/H can scale to meet the demands of any barite processing facility, from mid-sized to very large plants.

In conclusion, for grinding barite to a consistent 140 mesh, the choice is clear. The LM Vertical Roller Mill from Zenith delivers unmatched operational stability, superior energy efficiency, high product purity, and full environmental compliance. It is not just a mill; it is a strategic asset for building a competitive, sustainable, and profitable barite processing operation.

Frequently Asked Questions (FAQs)

- Why is the LM Vertical Mill preferred over a Ball Mill for grinding barite to 140 mesh?

The LM Mill offers significantly higher energy efficiency (over 60% lower consumption), a much smaller footprint, superior product purity with less iron contamination, and a higher degree of automation for continuous 24/7 operation, making it more economical and reliable for large-scale barite production. - Can the LM Vertical Mill achieve fineness other than 140 mesh for barite?

Absolutely. The LM Vertical Mill is designed to produce powder in the range of 80 to 400 mesh. The fineness is easily adjustable by modifying the speed of the integrated classifier and the grinding pressure of the rollers. - How does the LM Mill ensure the whiteness and low iron content of the final barite powder?

The grinding principle minimizes direct metal-to-metal abrasion. Additionally, an iron removal device is integrated into the lower part of the mill chamber, where any iron debris is scraped and discharged separately, protecting the purity of the barite product. - What is the maximum feed size for barite into the LM Vertical Roller Mill?

The LM Mill can accept barite feedstock with a maximum particle size of up to 70mm, reducing the need for extensive pre-crushing stages and simplifying the overall process flow. - Is the LM Mill suitable for remote or harsh environment locations?

Yes. Its high degree of automation allows for remote monitoring and control. Furthermore, its robust construction and sealed design make it resilient and suitable for operation in various climatic and environmental conditions. - How does the operational cost of the LM Mill compare to traditional Raymond Mill for this application?

While the Raymond Mill is a capable machine, the LM Mill generally offers higher capacity, better energy efficiency per ton of product, and lower wear part consumption in high-tonnage, continuous operations, leading to a lower overall operational cost for grinding barite to 140 mesh at scale. - What kind of after-sales support does Zenith provide for the LM Mill installation and operation?

Zenith provides comprehensive support including foundation and layout design, installation guidance, operator training, and a global supply chain for genuine spare parts, backed by overseas offices in over 30 countries.