Algeria seeks to purchase bentonite grinding machines

2025-11-09 06:31:20

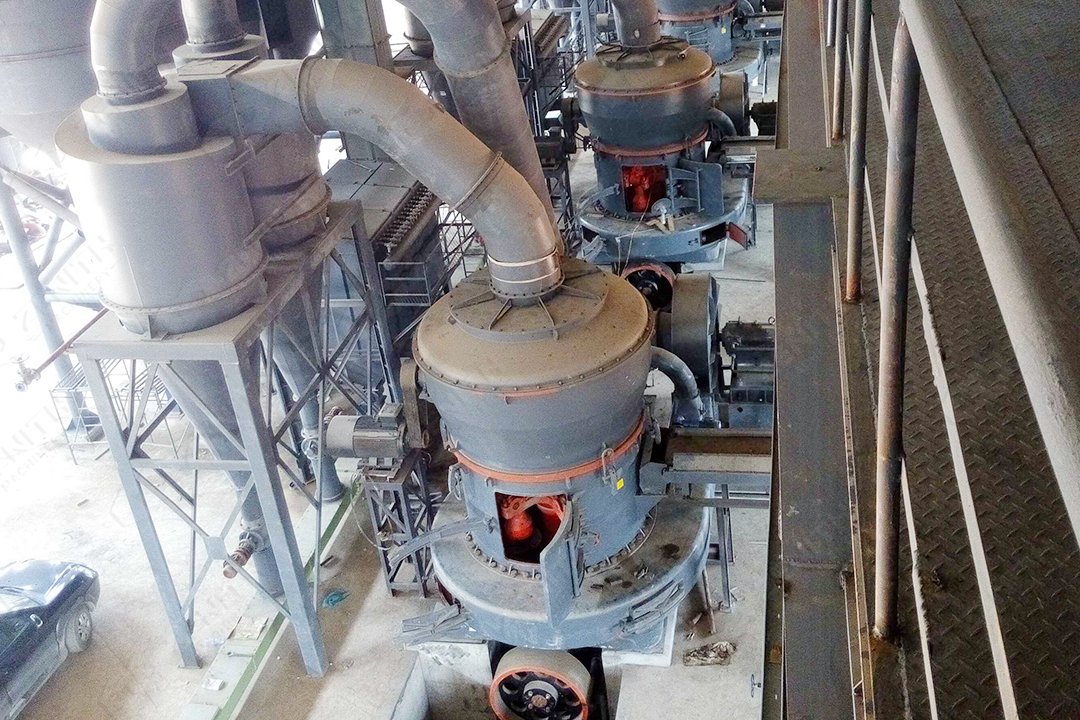

The Algerian industrial sector is currently experiencing significant growth, particularly in the domains of agriculture, construction materials, and chemical processing. This expansion has created substantial demand for high-quality bentonite processing equipment capable of transforming raw bentonite clay into various powder finenesses for diverse applications. As a leading player in industrial grinding machinery, Zenith Machinery has been closely monitoring these market developments and stands ready to provide optimal solutions for Algeria's bentonite processing needs.

Bentonite, with its exceptional absorption and swelling properties, requires specialized grinding equipment to preserve its natural characteristics while achieving the desired particle size distribution. The Algerian market specifically requires machines capable of producing powders ranging from coarse aggregates for foundry applications to ultra-fine powders for pharmaceutical and cosmetic uses. Understanding these varied requirements is crucial for selecting the appropriate grinding technology.

_1762641080614.jpg)

For bentonite processing operations requiring fine powders between 80-400 mesh, Zenith's MTW European Trapezium Mill presents an ideal solution. This advanced grinding system offers capacities ranging from 3 to 22 tons per hour while consuming 60% less energy compared to traditional ball mills. The MTW series incorporates a modular impeller adjustment system that allows operators to easily modify output fineness without requiring extensive downtime or technical expertise. For Algerian processing plants dealing with variable bentonite quality, this flexibility proves particularly valuable.

Algerian industrial developers will appreciate the MTW series' compact footprint, which significantly reduces infrastructure investment costs. The integrated production system handles everything from bulk material feeding to finished powder collection, eliminating the need for multiple separate units. The high-efficiency impeller fan, with its 85% air induction efficiency, ensures optimal system performance even in Algeria's diverse climatic conditions, from coastal humidity to desert aridity.

For large-scale bentonite processing facilities requiring continuous 24-hour operation, Zenith's LM Vertical Grinding Mill offers unparalleled reliability. With capacity options extending to 340 tons per hour, this vertical roller mill system excels in maintaining consistent product quality through automated control systems. Algerian operators can benefit from the remote monitoring capabilities, allowing for efficient management of multiple production lines from centralized control rooms.

The LM Vertical Mill's environmental performance aligns perfectly with Algeria's increasing focus on sustainable industrial development. The completely sealed system operates under negative pressure, preventing dust emissions and ensuring worker safety. This feature is particularly important for bentonite processing, where fine particles can pose respiratory hazards. The system's low noise generation further contributes to improved working conditions.

When ultra-fine bentonite powders are required for specialized applications, Zenith's LUM Ultrafine Vertical Grinding Mill delivers exceptional performance. Capable of producing powders from 325 to 2500 mesh, this advanced system incorporates German powder separation technology and Taiwanese grinding roller innovations. For Algerian companies targeting high-value bentonite applications in plastics, PVC, and advanced materials, the LUM series provides the precision grinding necessary to compete in international markets.

_1762641080618.jpg)

The XZM Ultrafine Grinding Mill represents another excellent option for Algerian processors needing precise control over final product specifications. With arbitrary fineness adjustment between 325 and 3250 meshes, this mill enables producers to quickly adapt to changing market demands. The variable frequency drive on the classifier allows operators to fine-tune particle size distribution through simple control panel adjustments, making it accessible for technicians with varying experience levels.

For operations focusing on coarse bentonite powders for applications like animal feed additives or construction materials, Zenith's Hammer Mill series offers robust performance with outputs ranging from 3 to 50 tons per hour. The optimized cavity design and high manganese steel lining ensure extended service life even when processing abrasive bentonite materials. Algerian customers will appreciate the minimal maintenance requirements and straightforward operation, reducing dependency on specialized technical support.

Zenith's global experience, evidenced by our presence in over 180 countries and overseas offices in more than 30 nations, ensures that our equipment is designed to perform reliably in diverse operating conditions. Our certifications including ISO, CE, and CU-TR demonstrate our commitment to international quality standards – an important consideration for Algerian companies targeting export markets.

The Algerian industrial sector's growth trajectory presents exciting opportunities for bentonite processing operations. By selecting appropriate grinding technology from Zenith's comprehensive product range, Algerian companies can optimize their production efficiency, product quality, and operational costs. Our technical support team stands ready to assist with equipment selection, installation guidance, and operational training to ensure successful implementation of these advanced grinding systems.

_1762641080624.jpg)

As Algeria continues to develop its industrial capabilities, having access to world-class grinding technology becomes increasingly important. Zenith's diverse range of mills, from the energy-efficient MTW series to the high-precision LUM vertical mills, provides Algerian businesses with the tools needed to compete effectively in both domestic and international markets. Our commitment to research and development ensures that we continue to innovate, providing our Algerian partners with cutting-edge solutions for their evolving bentonite processing requirements.

Frequently Asked Questions

What is the typical delivery time for Zenith grinding mills to Algeria?

Standard delivery time ranges from 30 to 60 days depending on the specific model and configuration. We expedite shipping through our established logistics channels to North Africa.

Can Zenith provide technical training for our operational staff in Algeria?

Yes, we offer comprehensive training programs either at our facilities or on-site in Algeria. Training covers operation, maintenance, and troubleshooting procedures.

How does the energy consumption of Zenith mills compare to traditional ball mills?

Our MTW and MTM series consume approximately 60% less energy than traditional ball mills of equivalent capacity, significantly reducing operational costs.

What after-sales support does Zenith provide in Algeria?

We maintain a network of service engineers and provide remote technical support, spare parts supply, and regular maintenance services through our regional partners.

Can your mills handle the specific moisture content found in Algerian bentonite deposits?

Our mills are designed with adjustable drying capabilities and can be configured to handle various moisture levels typical of Algerian bentonite sources.

What fineness range can be achieved with your equipment for bentonite processing?

Our equipment range covers from coarse 0-3mm powder to ultra-fine 3250 mesh, allowing processing for any bentonite application requirement.

Do you provide custom solutions for specific production requirements?

Yes, our engineering team can customize mill configurations, feeding systems, and collection equipment to match your specific bentonite processing needs.