Working principle and applicable materials of Raymond mill

2025-10-17 13:13:24

Of course. Here is a detailed explanation of the working principle and suitable materials for a Raymond Mill (Raymond Roller Mill) in English.

---

### **Raymond Mill (Raymond Roller Mill): Working Principle and Suitable Materials**

A Raymond Mill, also known as a Raymond Roller Mill, is a widely used grinding equipment for pulverizing non-metallic minerals and various other materials into fine powder. Its design is characterized by high efficiency, reliability, and a wide range of adjustable fineness.

#### **I. Working Principle**

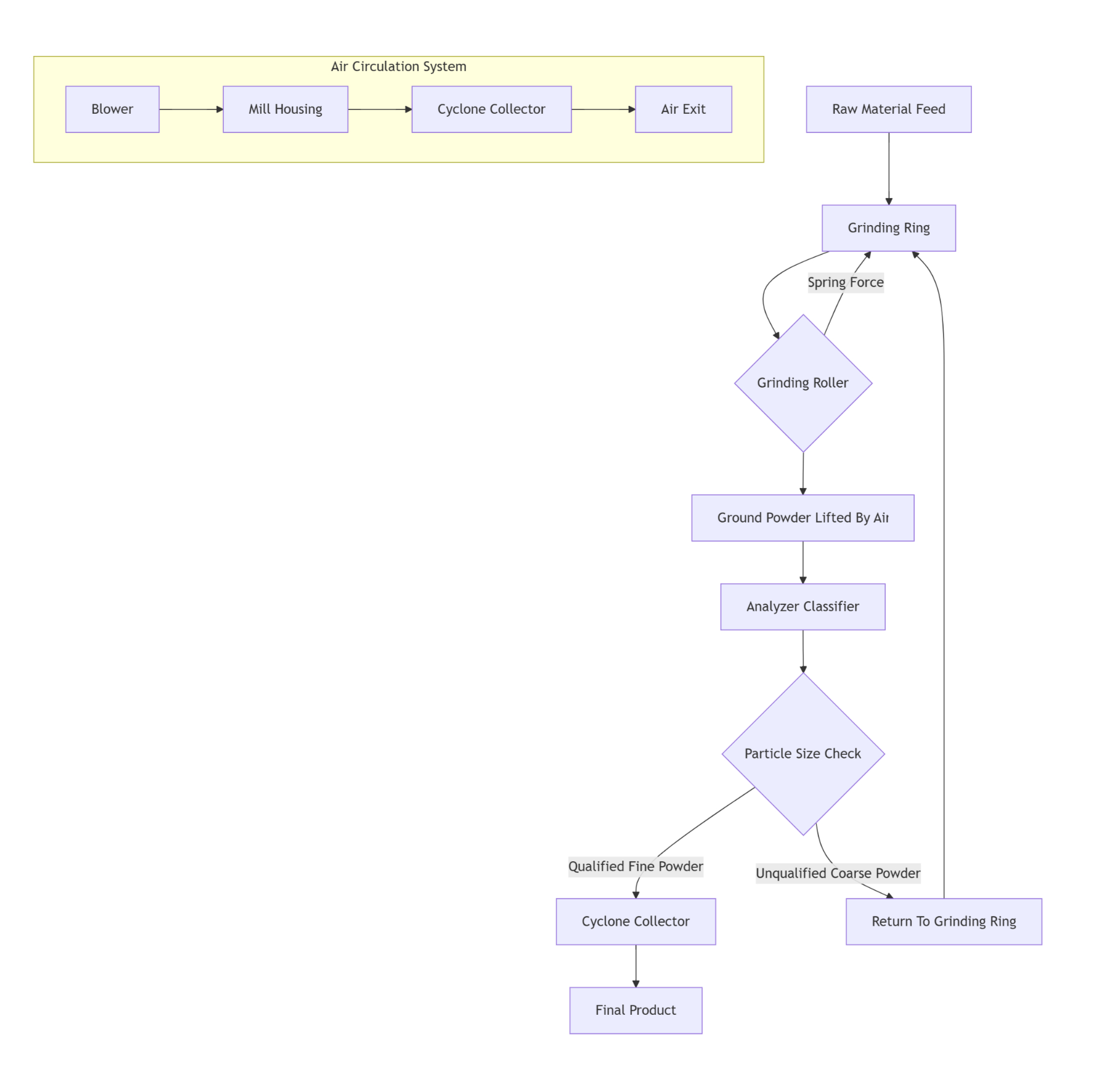

The operation of a Raymond Mill is a continuous process that integrates grinding, classification, and collection. The following flowchart outlines the core stages of its operation:

As shown in the chart, the process begins with **A**: uniformly fed raw material. The core mechanical grinding action occurs between the **B**: **Grinding Ring** (bull ring), which is fixed and stationary, and the **C**: **Grinding Rollers**, which rotate and gyrate around their own axes due to friction with the ring.

These rollers are pressed against the inner surface of the grinding ring by a **Spring Force** system, creating the powerful compressive force needed to crush the material.

Once ground, the powder is **D**: lifted by the airflow generated by the **K**: **Blower**. This air stream carries the powder upward to the **E**: **Analyzer Classifier**.

The classifier is a critical component. It's a rotating cage with vanes that creates a centrifugal force. Here, the **F**: **Particle Size Check** happens:

* **Unqualified Coarse Powder**: Particles that are too heavy (too coarse) are thrown to the periphery and fall **H**: back onto the grinding ring to be reground. This creates a continuous grinding cycle.

* **Qualified Fine Powder**: Particles that are fine enough pass through the classifier vanes and are carried by the air stream to the **G**: **Cyclone Collector**.

In the cyclone collector, the powdered material is separated from the air stream due to a sudden change in direction and centrifugal force. The final product **I**: is discharged from the bottom of the cyclone.

The air circulation system **J** is key. After passing through the cyclone, the cleaned air may be recirculated back to the blower in a closed-loop system, or a portion may be vented, with fresh air introduced, depending on the design and process requirements.

#### **II. Suitable Materials**

Raymond Mills are highly versatile but are best suited for grinding **non-flammable and non-explosive materials** with a Mohs hardness of less than 7 and a humidity below 6%.

**Commonly processed materials include:**

* **Calcium-Based Minerals:**

* **Calcite** & **Calcium Carbonate (CaCO₃)**

* **Limestone**

* **Chalk**

* **Whiting**

* **Silicate Minerals:**

* **Barite**

* **Gypsum**

* **Talc**

* **Mica**

* **Bentonite**

* **Other Industrial Minerals:**

* **Potassium Feldspar**

* **Dolomite**

* **Marble**

* **Phosphate Rock**

* **Active Carbon**

* **Clay**

#### **III. Key Advantages**

* **High Efficiency & Low Energy Consumption:** The rolling pressure principle consumes less energy than impact-based grinding.

* **Wide Range of Adjustable Fineness:** Can typically produce powder from 80 to 400 mesh (180 to 37 microns). Modern models can achieve up to 600 mesh.

* **High Reliability:** Key grinding components are durable, and the system is designed for continuous operation.

* **Excellent Environmental Performance:** The fully enclosed system with an efficient baghouse or pulse dust collector ensures minimal dust emission.

In summary, the Raymond Mill is a workhorse of the mineral grinding industry, offering an efficient and reliable solution for producing fine powders from a vast range of medium-hard materials.