Citric acid company seeks to purchase a 325 mesh limestone powder production line (all-inclusive).

2025-11-20 18:55:08

For a citric acid manufacturing company, the selection of a limestone powder production line is not merely an equipment purchase; it is a strategic investment in the fundamental raw material that directly impacts product quality, production efficiency, and overall operational cost. The requirement for a 325 mesh fine powder, a critical component in the neutralization and purification stages of citric acid production, demands a grinding solution that is precise, reliable, and economically viable. Shanghai Zenith Machinery, with its global engineering footprint and specialized expertise in industrial powder processing, presents a comprehensive analysis of optimal solutions for this specific application.

The production of citric acid involves complex biochemical processes where limestone (primarily calcium carbonate) is used to adjust pH levels and precipitate impurities. The fineness of the limestone powder, specifically 325 mesh (approximately 45 microns), is crucial. It ensures a high and rapid reactivity, leading to efficient neutralization and a purer final product. An inconsistent or coarse powder can result in incomplete reactions, higher consumption of raw materials, and potential quality deviations in the citric acid. Therefore, the core of the production line must be a grinding mill capable of delivering a consistent 325 mesh product with high efficiency and minimal operational hassle.

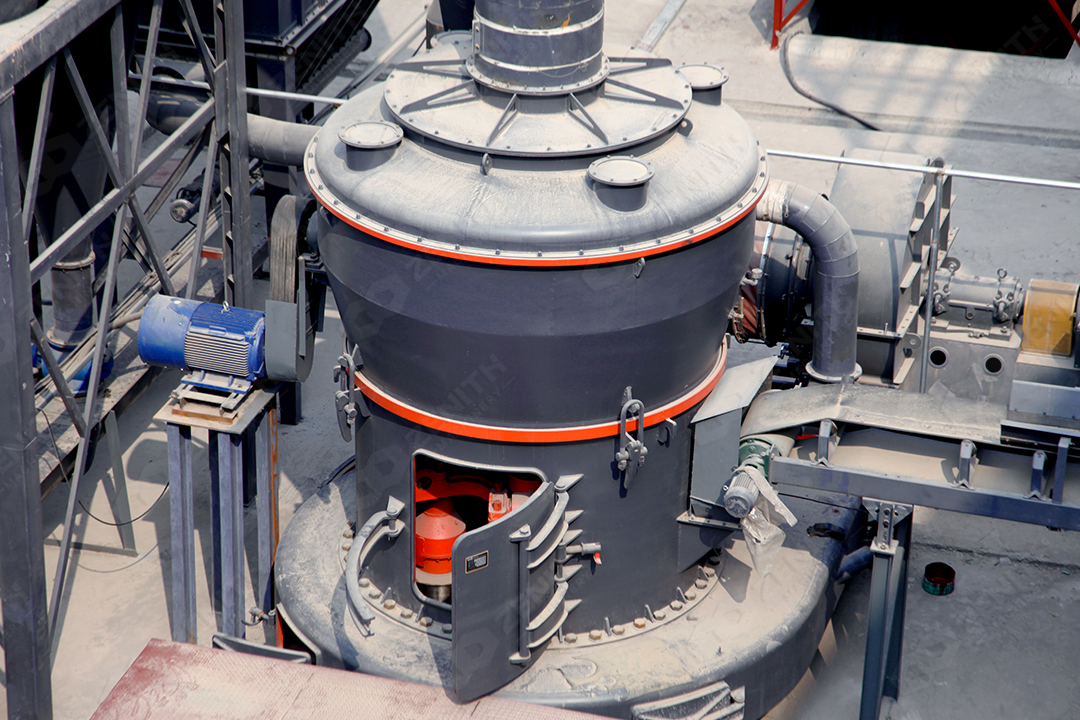

Among Zenith's robust portfolio, several mills are engineered to meet the 325 mesh specification with exceptional performance. The MTW European Trapezium Mill stands out as a premier choice. Designed for producing fine powders in the 30-325 mesh range with capacities up to 22 T/H, it aligns perfectly with the requirement. Its key advantage lies in its remarkable energy efficiency, consuming over 60% less power than a traditional ball mill of the same capacity. For a continuous process like citric acid manufacturing, this translates to significant long-term cost savings. Furthermore, the MTW series features an advanced modular impeller system, allowing for easy adjustment of output fineness. This ensures that the 325 mesh target can be consistently met and even fine-tuned if process requirements change.

Another proven workhorse is the MTM European Trapezium Mill. With over 30 years of technological evolution, this mill is renowned for its stability and practicality in generating 80-325 mesh mineral powder. It shares the same benefits of lower occupied area and reduced energy consumption as the MTW series. Its enduring popularity is a testament to its adaptability to various materials and its low initial investment cost, making it an excellent all-inclusive solution for companies seeking proven reliability.

_1763636108817.jpg)

For operations prioritizing a high degree of automation and space efficiency, the LM Vertical Grinding Mill presents a compelling option. Its capacity range is vast (3-340 T/H), and it is designed for 24/7 continuous operation—a critical feature for large-scale citric acid plants. The LM mill operates under a sealed, negative-pressure system, ensuring no dust spillage and a clean working environment, which is paramount in food-grade chemical production. Its automated control system allows for remote operation and monitoring, reducing labor costs and enhancing process consistency. The compact integrated design also reduces the footprint of the entire production line by approximately 50% compared to ball mill systems.

While the aforementioned mills are ideal for the 325 mesh target, Zenith's capability extends far beyond. For instance, the XZM Ultrafine Grinding Mill and LUM Ultrafine Vertical Grinding Mill are engineered for much finer applications, up to 3250 mesh. This highlights Zenith's technical depth, assuring clients that the technology for a 325 mesh line is well within its core, mature product range. The 'all-inclusive' nature of the inquiry is also addressed by Zenith's holistic approach. A complete production line encompasses more than just the grinding mill; it includes jaw crushers for primary size reduction, electromagnetic vibrating feeders, bucket elevators, and state-of-the-art pulse dust collectors. Zenith provides this integrated system, ensuring all components are perfectly matched for optimal performance and seamless operation.

Choosing Zenith as a partner means more than just acquiring machinery. It means leveraging a global company with ISO, CE, and CU-TR certifications, ensuring international quality and safety standards. With a marketing network covering over 180 countries and overseas offices in more than 30 nations, Zenith offers unparalleled after-sales support, technical service, and spare parts supply. For a citric acid company, this global support infrastructure provides peace of mind and minimizes operational downtime.

In conclusion, the quest for a 325 mesh limestone powder production line finds a technically sound and commercially astute partner in Shanghai Zenith Machinery. Whether the optimal solution is the energy-efficient MTW Mill, the time-tested MTM Mill, or the automated LM Vertical Mill, Zenith possesses the engineering expertise and project execution capability to deliver a turnkey, all-inclusive system that guarantees product quality, operational efficiency, and a strong return on investment for years to come.

Frequently Asked Questions

What is the typical lead time for a complete 325 mesh limestone production line?

Lead times vary based on the specific model and configuration, but typically range from 30 to 90 days after finalizing all technical details and commercial terms.

Do you provide installation and commissioning services for the production line?

Yes, we offer comprehensive technical services, including foundation drawing guidance, installation supervision, and on-site commissioning by our experienced engineers to ensure the line operates optimally.

How does the energy consumption of the MTW Mill compare to a traditional Raymond Mill?

The MTW European Trapezium Mill is significantly more efficient. It features a high-efficiency impeller fan that improves air induction efficiency from 62% to 85%, leading to overall lower energy consumption for the same output.

Can the production line be automated for remote monitoring and control?

Absolutely. Our LM Vertical Grinding Mill and other advanced models come equipped with automatic control systems that allow for remote control and local operation, enabling labor-free workshop operation and easy maintenance.

What kind of after-sales support can we expect after the purchase?

We provide lifelong technical consultation and support. Our global network ensures prompt service. We also offer online operation training and detailed manuals for your staff.

Is the output fineness adjustable should our production requirements change in the future?

Yes, mills like the MTW and XZM series are designed with adjustable fineness. The XZM mill, for example, can be arbitrarily adjusted between 325 and 2500 mesh via a VFD on the classifier.

What measures are in place to ensure environmental compliance, particularly regarding dust?

All our grinding systems operate under negative or positive pressure and are equipped with high-efficiency pulse jet bag dust collectors, ensuring emissions meet stringent international environmental protection standards.