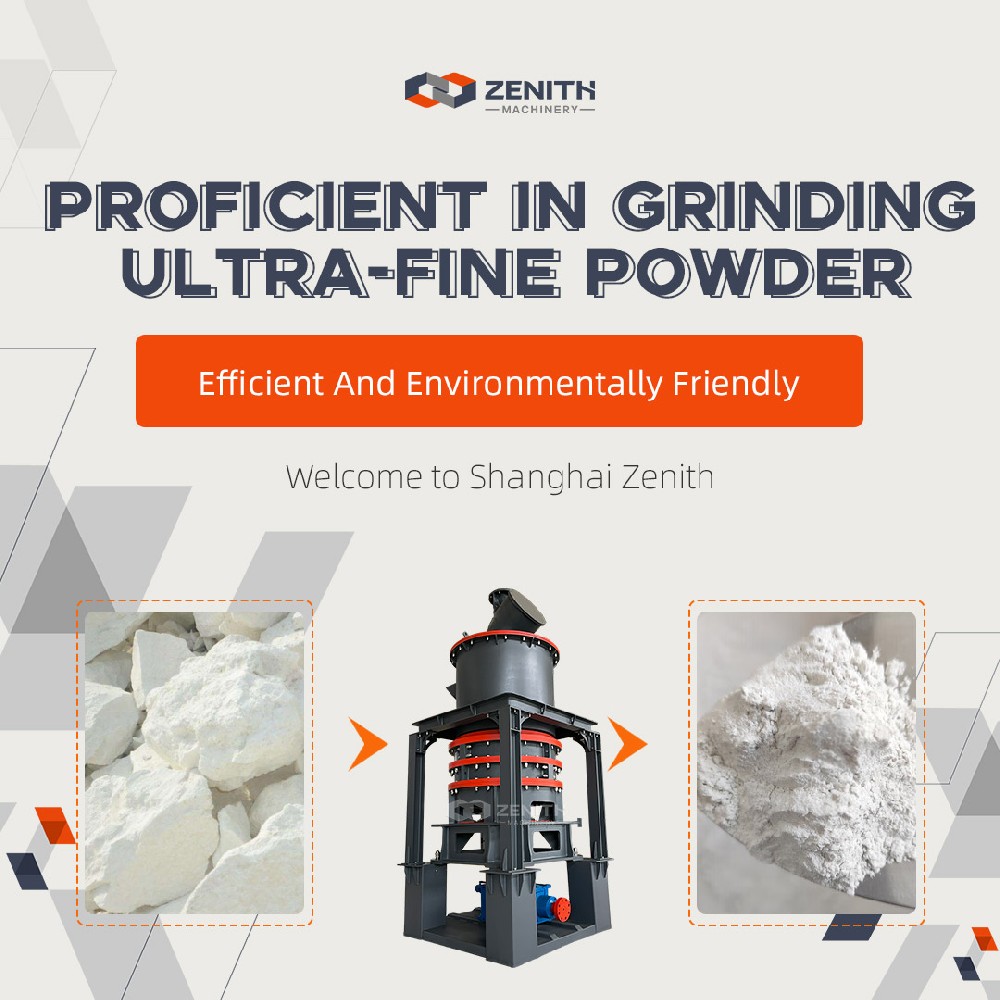

Ring Roller Micro-Powder Mill Operating Principle and Process

2025-10-29 17:07:04

The ring roller mill, also known as a roller press mill, uses multiple layers of ring rollers to crush, impact, and grind materials to produce powder. Capable of producing finenesses ranging from 150 to 3000 mesh in one operation, it is widely used for producing ultrafine powders of non-metallic minerals such as talc, calcite, calcium carbonate, dolomite, potassium feldspar, bentonite, kaolin, graphite, carbon, and carbon black. Its operating principle is as follows:

The main motor drives the main shaft and the rotating discs through a speed reducer. The rotating discs, via pins, drive dozens of ring rollers, which roll and rotate within the grinding roller table. After being crushed into small particles by the crusher, the bulk material is fed into the storage bin by an elevator. Feeding equipment such as an electromagnetic vibrating feeder or belt conveyor evenly delivers the material to the center of the upper turntable. Centrifugal force disperses the material toward the periphery of the turntable and drops it into the grinding rollers, where it is crushed layer by layer by the rollers, pressed, rolled, and ground. Finally, the crushed material is carried by wind into the classifier for sorting. Qualified fine powder is discharged from the mill along with the airflow and collected by the dust collector as the finished product. Unqualified material falls back into the grinding chamber under the action of the classifier and is re-ground with the newly fed material, completing the entire grinding process. The airflow containing a small amount of fine dust is purified by a pulse dust collector and discharged through a fan and muffler.