Complete set of mechanical equipment for dolomite grinding production line

2025-10-18 13:22:42

Of course. Here is a detailed and professional overview of a complete dolomite powder grinding production line machinery, presented in English suitable for technical specifications and business inquiries.

---

### **Complete Set of Dolomite Powder Grinding Plant Machinery**

This configuration is designed for a turnkey solution to process dolomite rock into fine or ultra-fine powder for various industrial applications such as construction, agriculture, glass, and ceramics.

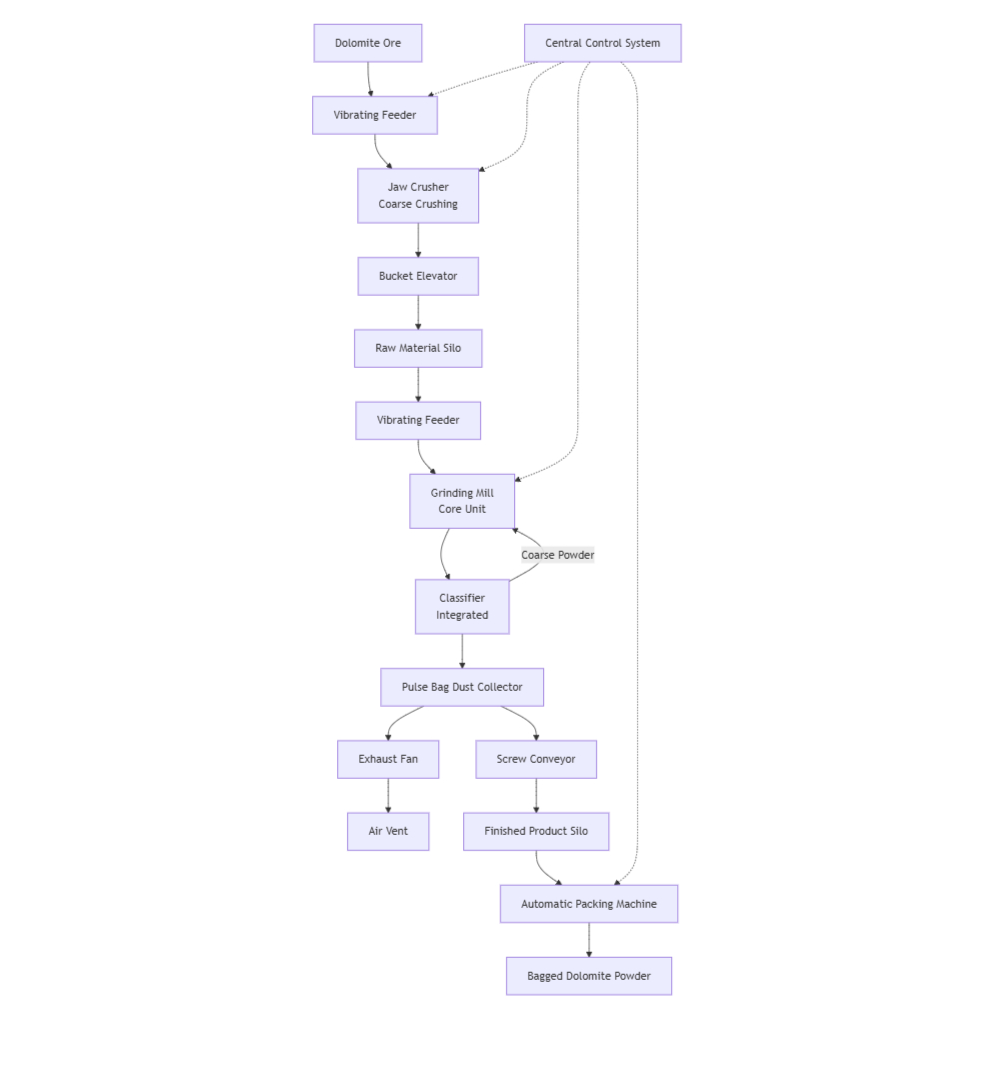

#### **1. Complete Production Line Flowchart**

The entire process, from raw material to packaged product, is illustrated below:

#### **2. Detailed Equipment List & Function Description**

| No. | Equipment Name | Key Function & Technical Description |

| :--- | :--- | :--- |

| 1 | **Vibrating Feeder** | Uniformly and continuously feeds raw dolomite ore (with a max. size of <500mm) to the jaw crusher. Ensures stable operation and prevents blockage. |

| 2 | **Jaw Crusher** | Performs primary (coarse) crushing to reduce the dolomite rock to a smaller size (typically below 30-50mm). This is essential for efficient grinding in the next stage. |

| 3 | **Bucket Elevator** | Lifts the crushed dolomite to the top of the plant for storage in the raw material silo, facilitating a gravity-fed system. |

| 4 | **Raw Material Silo & Vibrating Feeder** | Provides buffer storage and ensures a steady, controlled feed of crushed dolomite into the grinding mill. |

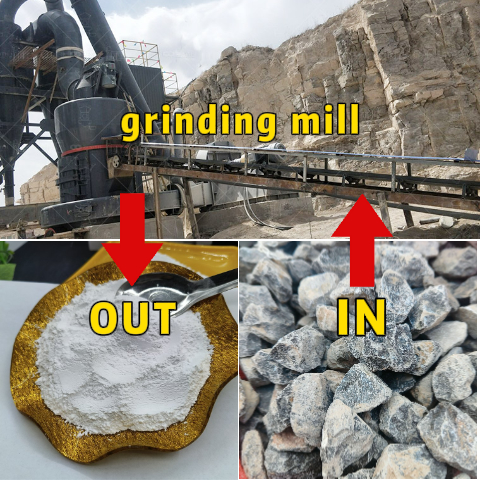

| 5 | **Core Grinding Mill** | **The heart of the plant.** Grinds the dolomite into powder. The choice of mill depends on the required product fineness and capacity. |

| 6 | **Classifier (Powder Separator)** | Integrated with the grinding mill. It precisely separates the fine powder (product) from the coarse powder. The coarse powder is returned to the mill for re-grinding, creating a closed-circuit system for high efficiency. |

| 7 | **Pulse Jet Baghouse Dust Collector** | **Core environmental and collection equipment.** It captures over 99.9% of the fine powder from the air stream, ensuring high product yield and a dust-free, environmentally friendly operation. |

| 8 | **Induced Draft Fan** | Provides the necessary airflow throughout the grinding system. It creates negative pressure, sucking the ground powder through the classifier and dust collector. |

| 9 | **Screw Conveyor / Airslide** | Transports the collected finished powder from the dust collector to the next stage. |

| 10 | **Finished Product Silo** | Stores the final dolomite powder before packaging, allowing for continuous production. |

| 11 | **Automatic Packing Machine** | Weighs and packs the finished powder into valve bags, big bags (ton bags), or other formats for storage and shipment. |

| 12 | **Central Electric Control System** | A PLC-based control panel that automates the entire production line, allowing for one-button start/stop, interlocked operation, and remote monitoring. It enhances safety and operational simplicity. |

#### **3. Key Configuration: Choice of Grinding Mill**

The selection of the core grinding mill is critical and depends on the desired final product.

* **For Coarse to Fine Powder (80 - 400 mesh):**

* **Recommended:** **MTW European Trapezium Mill** or **Raymond Mill (Roller Mill)**.

* **Advantages:** Mature technology, high cost-effectiveness, energy-efficient, and ideal for producing powder for construction materials (e.g., dry-mix mortar), agriculture, and fillers.

* **For Fine to Ultra-Fine Powder (400 - 2500 mesh):**

* **Recommended:** **Vertical Roller Mill** or **Ultra-fine Ring Roller Mill**.

* **Advantages:** Higher energy efficiency, integrated grinding and drying, and capable of producing high-value-added products for plastics, paints, and coatings.

* **For Large-Scale Production of Fine Powder:**

* **Recommended:** **Ball Mill** (often in a closed circuit with a classifier).

* **Note:** This is a traditional method but is less energy-efficient compared to modern vertical roller mills.

#### **4. Technical Highlights & Supplier Selection Advice**

* **Wear Part Material:** Ensure the grinding rollers and ring/table are made of **high-chromium alloy steel** or similar wear-resistant materials to combat dolomite's abrasiveness and extend service life.

* **System Sealing:** The entire system must be well-sealed to prevent dust leakage, protect the environment, and ensure product yield.

* **Turnkey Project (EPC):** Seek suppliers who can provide a **"Turnkey Project" or EPC (Engineering, Procurement, Construction)** service. This ensures a single point of responsibility from plant design, equipment manufacturing, installation, commissioning, to operator training.

* **Request a Grinding Test:** Always provide a sample of your dolomite to potential suppliers. A professional manufacturer will conduct a **free grinding test** to determine the most suitable equipment and provide a data-backed project proposal.

**In summary, a complete dolomite grinding plant is an integrated system where machinery selection, especially the grinding mill, is tailored to the specific product goals. Leading Chinese manufacturers like Guilin Hongcheng, Liming Heavy Industry, and SBM Group are well-equipped to provide such complete solutions.**