Case Study of Limestone Powdering Project in Algeria

800 mesh

XZM244 Ultrafine Grinding Mill

Project Overview

The client is the owner of a large limestone quarry in Algeria. Previously, they dealt in raw ore, but with increasing market demand for fine limestone powder, they decided to add a limestone powder production line. Given Zenith Machinery's excellent reputation and numerous successful case studies in the local market, the client chose Zenith Machinery without hesitation.

XZM series ultrafine mill are a ideal milling machine with advanced technology, which could produce 325 mesh to 2500 mesh with single classification. Its inner structure is relatively simple, which compromises the less downtime and easy for maintenance. The classifier is equiped with VFD to easy adjust the rotary speed of classification rotor, which makes convinient to get the requested powder size by setting on electric control panel. The produced mineral powders are widely used in paint, PVC, plastic, paper, chemical industries.

Features

1. Arbitrary Adjustment of Fineness

The product fineness of XZM Ultrafine Grinding Mill can be adjusted arbitrarily between 325 meshes and 2500 meshes, and can reach D97 < 5 micron at one time.

2. High Efficiency, Low Energy Consumption

To produce same powder under the same power, the XZM is 40% higher on efficiency and 70% lower on energy consumption than air-flow mill and stirring mill.

3. Safe Structural Design

There are no rolling bearings and screw in the grinding chamber. There is no problem of bearing and seal vulnerability and the hidden danger of screw loosening destroying.

4. Environmentally Friendly

XZM Ultrafine Grinding Mill adopts high-efficiency pulse dust collector and muffler. It has no dust pollution and noise pollution and fully meets the national environmental protection standards.

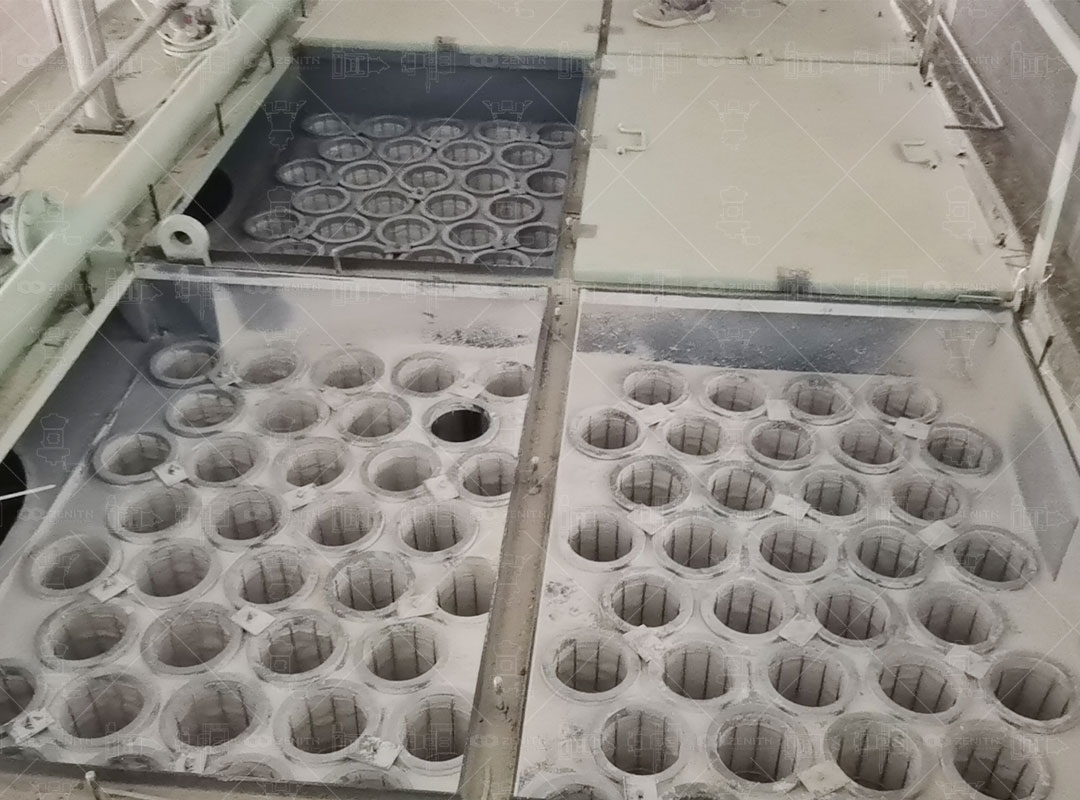

Photos from the scene